TIG Welding Method

When manufacturing an autoclave, one of the key stages is the welding of parts. This process is crucial because the main characteristic is airtightness. Properly welded elements ensure the airtightness of the body and the durability of the autoclave.Autoclaves by the “Ukrtpromtekh” company are welded using the TIG method in an argon environment. This method guarantees high-quality joints between parts that maintain their properties over a long period of operation. In this article, we will detail all the features of the TIG welding method.

Advantages and Disadvantages

Argon arc welding is a process where metal elements are fused by heating the electrode arc with argon. The use of argon is driven by its main feature – to protect metals from oxygen exposure.

The primary application of the TIG method in an argon environment is the food industry. Additionally, it is used in aviation, automotive, and oil extraction industries.

The advantages of TIG welding in an argon environment include:

- high quality of weld seams;

- full control over the arc state during welding;

- no metal splatter during welding;

- the ability to weld in various positions;

- absence of slag that can enter the equipment;

- a small heating zone that reduces the possibility of deformation;

- environmental friendliness – a small amount of harmful emissions into the atmosphere.

Some of the disadvantages of the method include:

- the process is much slower compared to other methods. Therefore, this method is suitable for welding thin metal, intricate, and high-tech parts that require precision and reliability. However, if you need to quickly connect parts, especially large ones, for example, during construction, this method will be inefficient and impractical;

- due to the use of inert gas (argon), welding in an argon environment is nearly impossible outdoors. However, if outdoor welding is unavoidable, special shields are used to enclose the workspace and increase argon supply.

During the manufacturing of our autoclaves, the TIG welding method is the best choice because quality and reliability come first, despite the lengthy process.

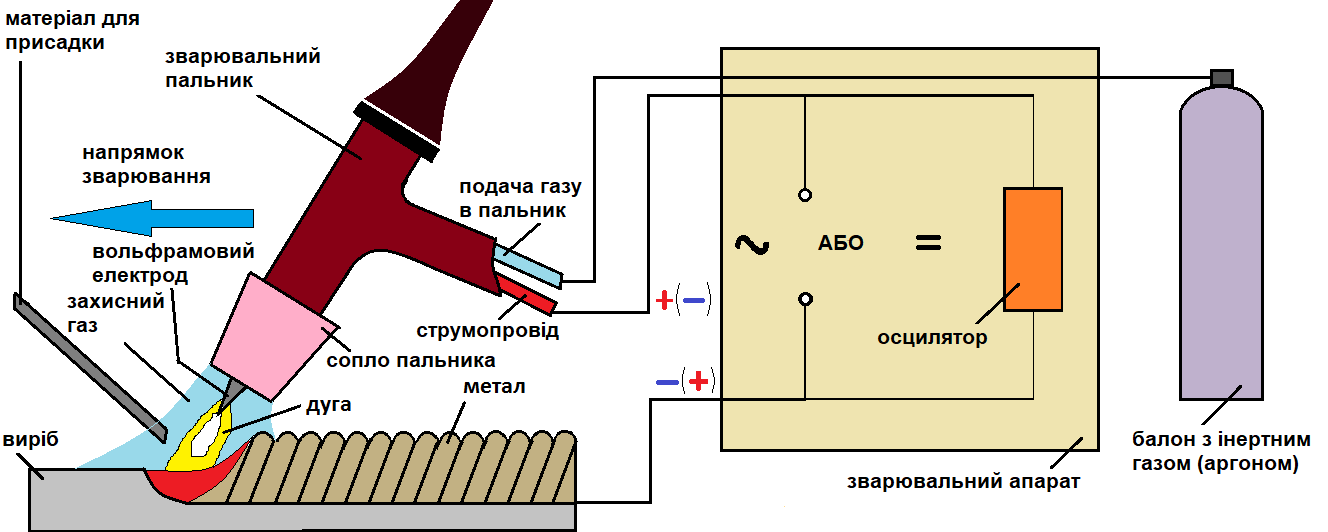

Welding Equipment

The TIG welding process requires specific equipment:

- TIG inverter (argon arc welding) ‒ this is the foundation of the entire process. The device converts direct current into alternating current, which is needed for this type of welding;

- Argon cylinder ‒ this gas is mainly used during welding, but helium can sometimes be used under the right conditions;

- Torch - a gun-like element attached to a hose connected to the gas cylinder. The torch is also equipped with a special holder that contains the electrode inside;

- Tungsten electrodes;

- Filler material ‒ wire or rod is commonly used. The metal from which the wire is made should be the same as the welded metal, and the thickness should match the size of this material.

TIG Welding Process

For welding with argon gas, two types of electrodes are used: consumable and non-consumable. Non-consumable electrodes are used when welding thin metals with a thickness of no more than one millimeter. The second method is used for metals with a thickness of more than two millimeters.

Non-consumable electrodes are called tungsten electrodes. Their melting point is 3410°C, and boiling point is 5900°C. When using such electrodes, the base material melts if its thickness is 3 millimeters. Due to this, tungsten electrodes have a very low consumption ‒ only ten milligrams are required for one meter of weld. For thicker metals, filler materials are needed. They must be manually fed to ensure a stronger connection.

Non-consumable electrodes provide fast weld formation, and the arc burns at a low voltage.

The main feature of welding in an argon environment is hermeticity. This is achieved through filler materials that are welded to the base metal. As a result, a hermetic weld is formed, ensuring the reliability and strength of the metal product.

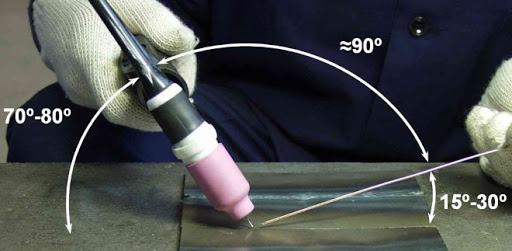

When welding stainless steel and corrosion-resistant metals, certain conditions must be met. The most important factor is maintaining smooth, steady movements without deviations, so the protective zone stays in line and the weld does not oxidize. To achieve this, remember these simple rules: hold the torch at an angle, and the angle between the torch and the metal should be about eighty degrees. The filler material should be held at a 90° angle. It is held in front of the arc and gradually introduced into the weld. It is not allowed to hold the wire or rod transversely to the arc.

Welding of Autoclaves

All seams in the autoclaves produced by "UKRPROMTEKH" are welded using the TIG method. Despite its high cost, this method fully justifies itself by providing high quality.

.jpg)

At our company, we employ highly qualified welders because this method requires special knowledge and skills. In addition to professionals, we also use tested equipment and high-quality materials that ensure the strength and durability of the connections.

The TIG method is the best way for autoclave production as it allows welding different types of metals with equal reliability.

If you wish to purchase autoclaves from "UKRPROMTEKH," you can choose the necessary model on our website. By calling our managers, you will receive comprehensive answers to your questions, along with valuable advice and recommendations. You can contact us at: (050) 376-60-86, (067) 370-27-22.

We also offer a wide range of other metal products: moonshine stills, cheese boilers, water heaters, picnic grills, smokehouses, etc. By choosing us, you will receive a quality product that simplifies the preparation of your favorite dishes.

Also read:

- Autoclave Operating Modes

- What is an Autoclave?

- Autoclave Hydraulic Tests

- How to Use an Autoclave

- How to Choose an Autoclave